Description

2. Empty the system. If the system is treated with conditioning agents, it is advisable to collect the system water in a special container so that it can be used at the end of the work.

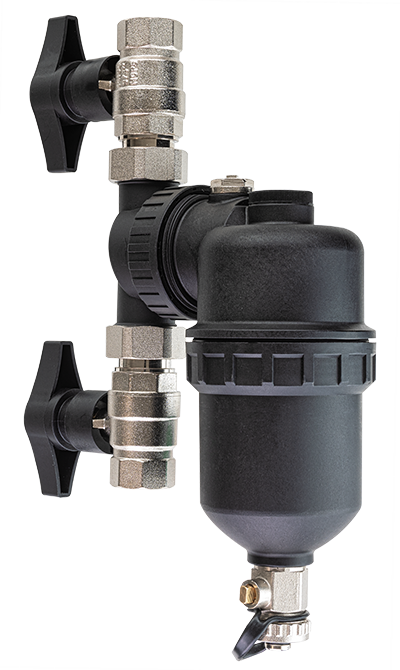

3. Always use the ball valves supplied when installing the sludge separator to facilitate maintenance, cleaning and flushing operations. It is recommended to measure the sludge separator with the valves installed as if they were running, in order to cut the chosen return pipe according to the total installation size.

4. During installation, turn the ring nut of the sludge separator with the arrow on the diverter body pointing in the direction of the system flow. Check that the O-ring is in its seat, then tighten. The fi lter housing can be oriented vertically or tilted by up to 45° in case of limited space.

5. A thorough cleaning is recommended with one of the Mayline HRplus, Mayline HR or Mayline CP cleaners for high-temperature systems and with Mayline SB for low-temperature systems. In both cases, rinse thoroughly with tap water.

6. Open the ball valves to load the system. Add 1% Mayline K32 conditioning agent for high-temperature systems, or 1% Mayline SBA for low-temperature systems. Then check all seals on the sludge separator and ball valves. Vent the air in the sludge separator using the air exhaust valve on top of the sludge separator.